Bild ist im Hintergrund eingefügt – mit einer Höhe von 50vh – Dieser Text ist Transparent

Precision at Every Stage – Automated Packaging of Medical Plastic Components

Efficient packaging automation for medical technology – fast, precise, and space-saving

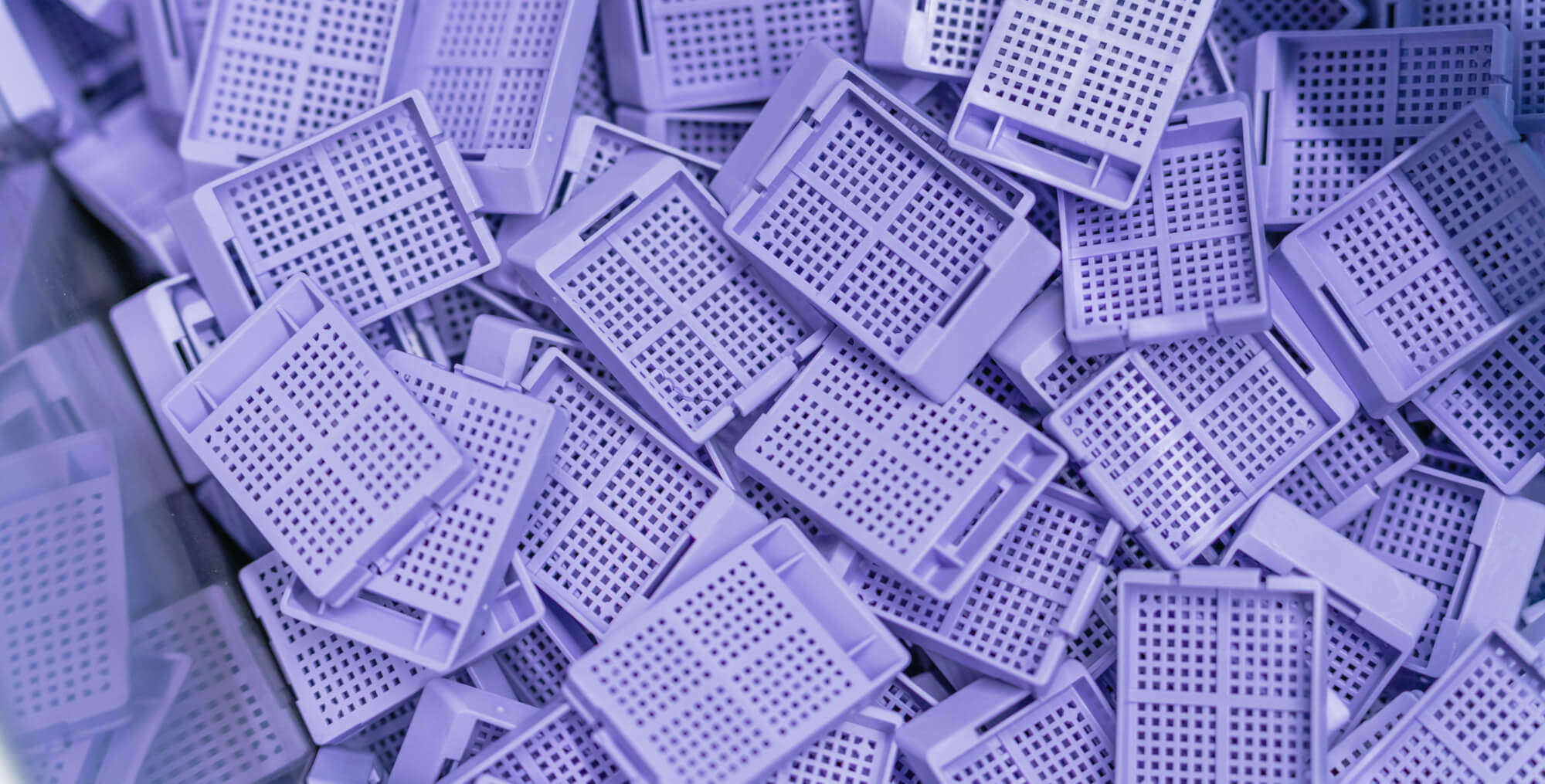

Sanowa PlastoTec GmbH, based in Leimen, Baden-Württemberg, specializes in high-quality plastic components for the medical and industrial sectors. One of its key products is tissue embedding cassettes, which are used in pathology labs and hospitals to secure and examine tissue samples.

To meet rising demand and stricter industry requirements, the company relies on our automation solution for the packaging of medical plastic components – ensuring maximum efficiency, process reliability, and hygiene.

Plastics / Medical Technology

Sanowa PlastoTec GmbH

Working with robomotion was consistently professional and reliable – from fast implementation to smooth commissioning. The new system has noticeably increased our efficiency and strengthened our competitiveness on the international market. Ongoing technical support also impresses with its speed and expertise.

Patrick Jahn, Managing Director, Sanowa PlastoTec GmbH

The Challenge

Packaging medical-grade plastic parts such as tissue embedding cassettes requires maximum precision and efficiency – especially with increasing production volumes.

When high volumes meet manual processes, bottlenecks, rising personnel requirements, and quality risks are often the result. This was exactly the challenge Sanowa PlastoTec GmbH faced. The previous manual stringing and packaging process for the cassettes could no longer keep up with growing demand.

They were looking for a solution for the automated packaging of medical plastic parts – one that was precise, compact, and hygienic. The new system had to reliably feed and align the delicate cassettes, automatically and safely process the strapping, and integrate seamlessly into the existing production line. At the same time, it needed to meet the hygiene requirements of medical technology and be flexible enough to scale for future needs.

The Solution

Automated packaging of medical plastic parts – fast & accurate

Manual handling and slow banding are a thing of the past. Today, a fully automated robotic solution takes care of every step – with speed, precision, and reliability.

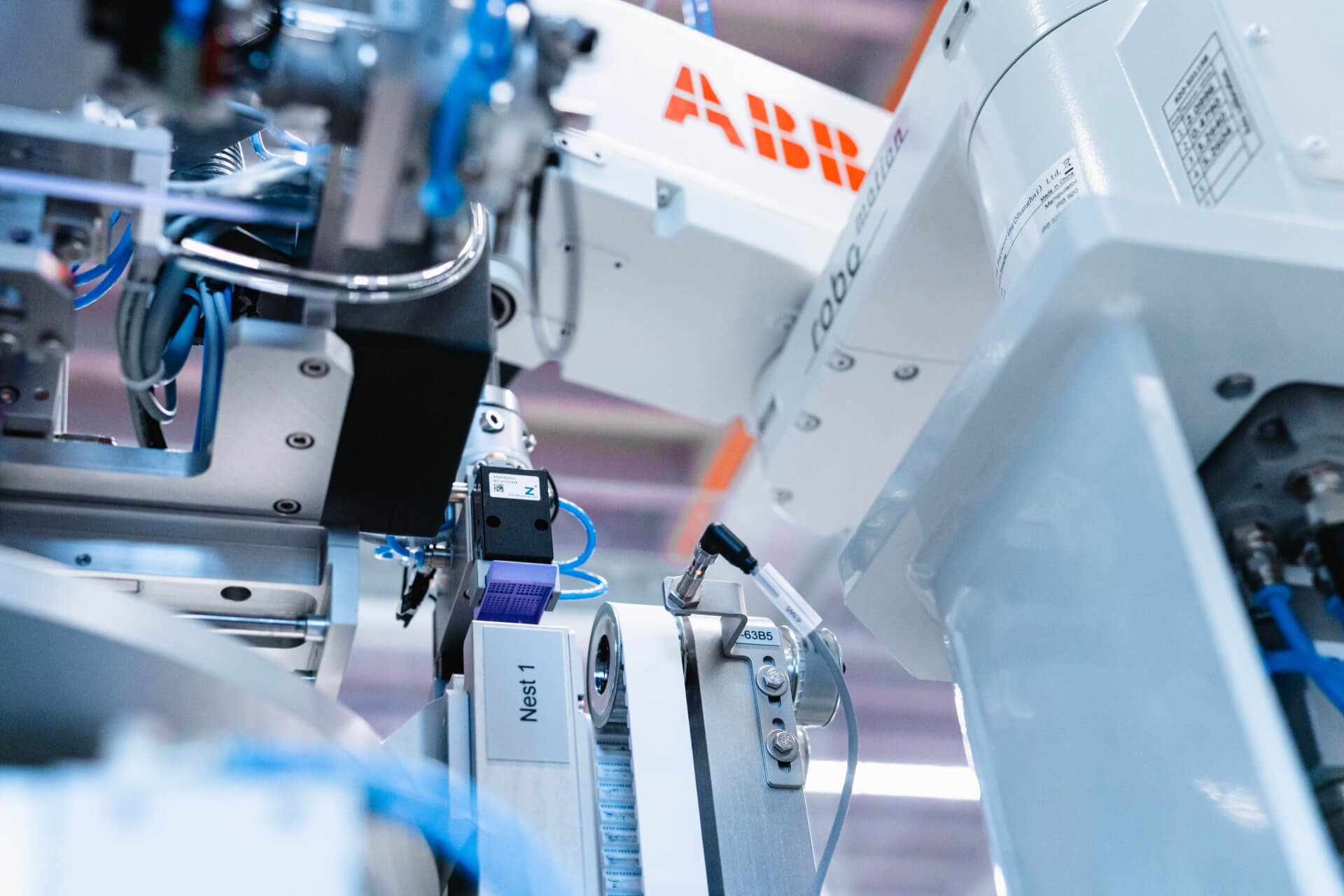

Automated feeding & stacking

Two vibratory bowl feeders separate and align the tissue embedding cassettes. An ABB IRB 920 SCARA robot picks up two cassettes at a time using a dual gripper and stacks them precisely into designated nests on a rotary indexing table.

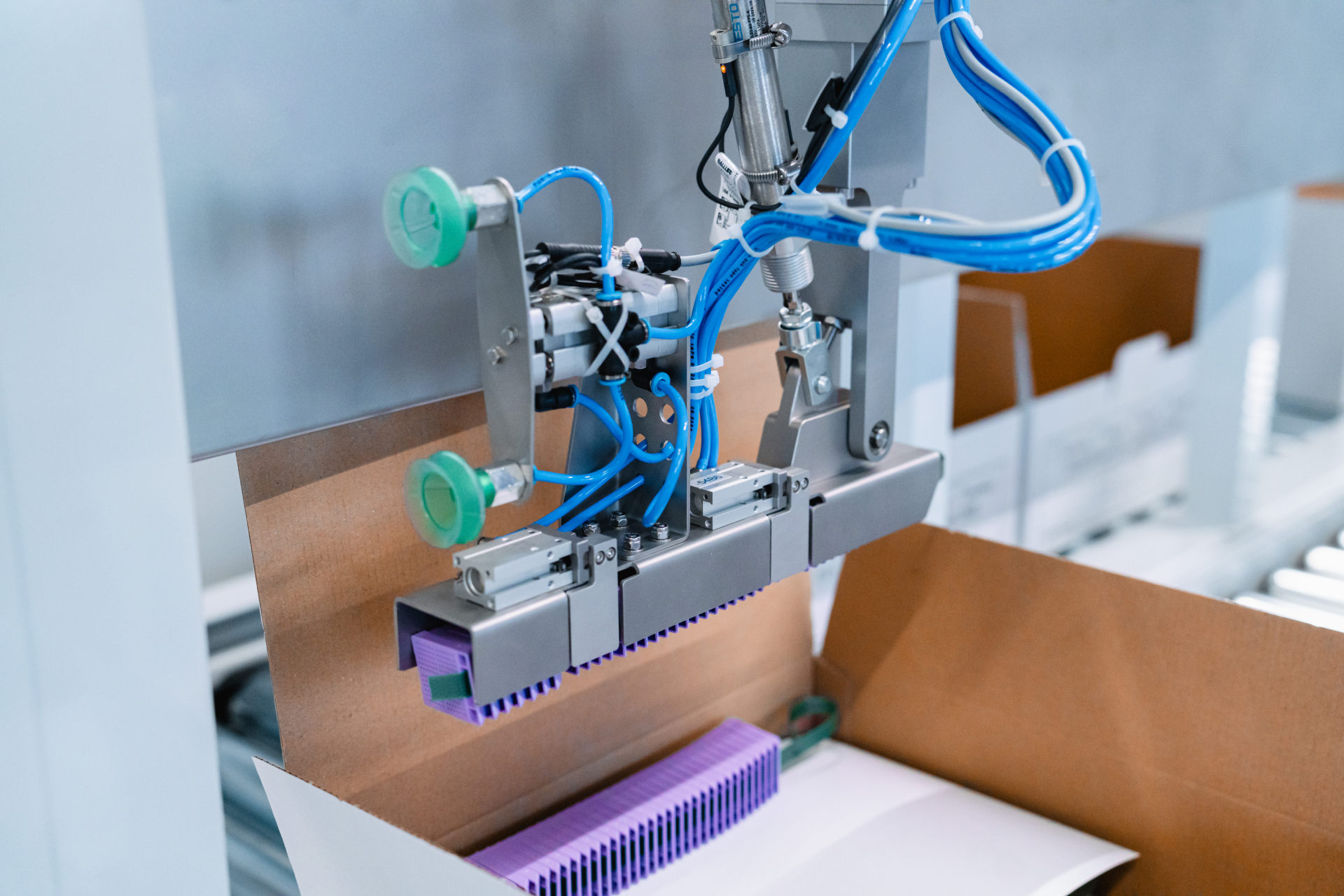

Bundling with strapping

Once two complete stacks are formed, the table indexes forward. A strapping band is automatically fed through the cassettes. A carrying loop is formed at the top and welded in place. At the bottom, the band is folded – creating stable, transport-safe packaging units.

Cartoning & interlayer handling

A 2-axis handling system picks up the bundled stacks, rotates them into the correct position, and places them precisely into pre-positioned cartons. Interlayers are automatically inserted between each layer to ensure stability and safe transport. Interlayer handling is seamlessly integrated into the process. A downstream conveyor transports the filled cartons to the operator for final additions and sealing.

High efficiency, easy scalability

The system achieves up to 6,000 parts per hour with a cycle time of just 1.2 seconds per cassette pair. Material replenishment is only required every 60 minutes.

Designed with future requirements in mind, the system can be upgraded for cleanroom use – featuring stainless steel components, sealed enclosures, and specially coated surfaces.

Sanowa PlastoTec benefits from a fully automated packaging solution that not only accelerates the entire process, but also ensures consistent quality, reduces manual workload, and can be flexibly scaled as needed – efficient today, future-ready tomorrow.

👉 Curious about Sanowa PlastoTec? Learn more here: Link to Sanowa PlastoTec GmbH website