Image is inserted in the background – with a height of 50vh – This text is transparent

May we help with the “coat”?

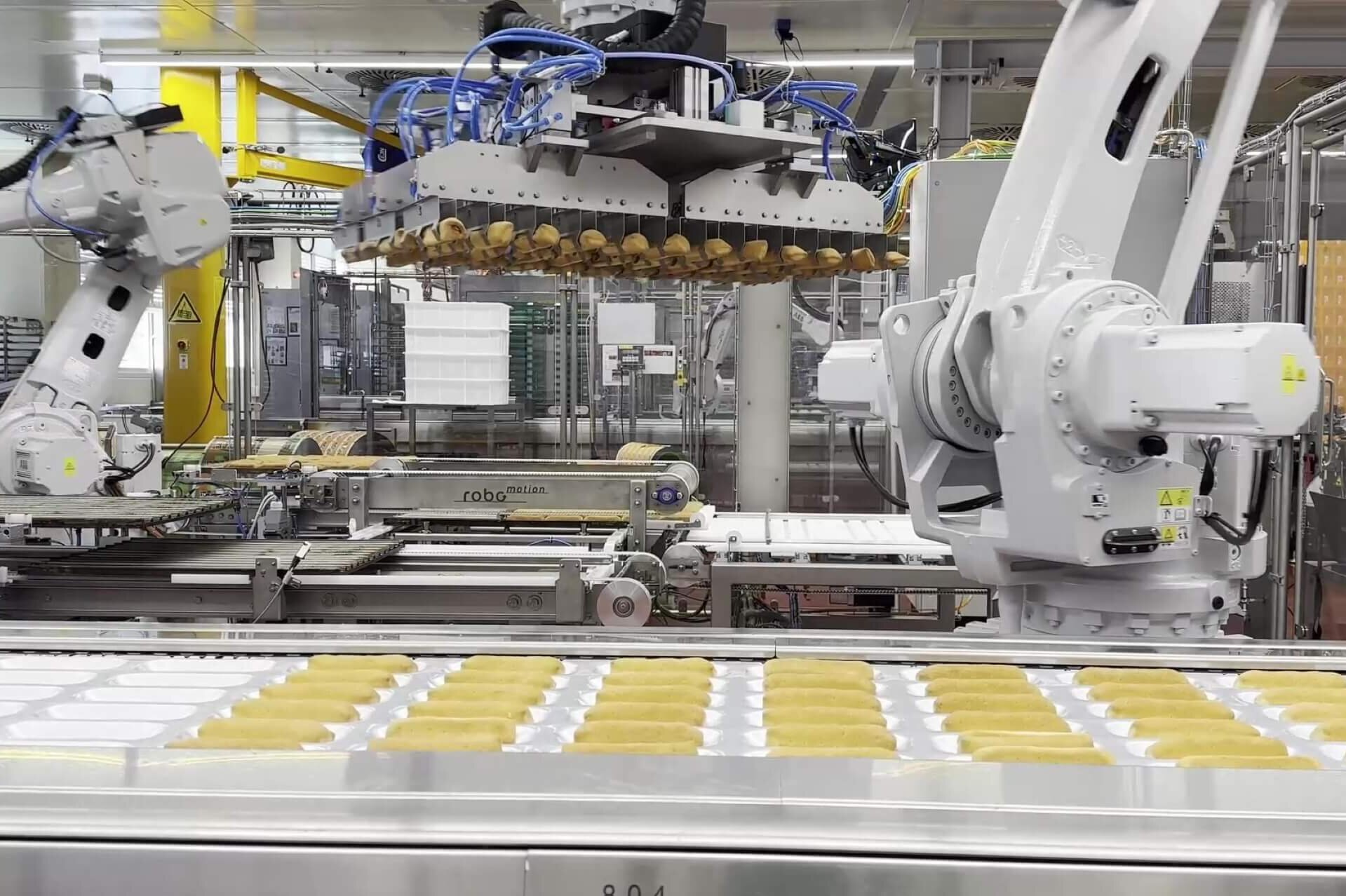

Innovative Automation Solutions for BiFi Production: Precise handling of dough products to packaging

LSI – Germany GmbH, known for its production of the popular Bifi sausages, is part of the global company Jack Links. Jack Links, market leader in the meat snacks segment in the USA, has production facilities in Germany, Brazil, New Zealand and the USA and sells its products in around 40 countries. Since 2006, Jack Links has continuously relied on robomotion’s automation solutions to increase the efficiency and quality of its production lines.

Food / Packaging

LSI Germany GmbH

As our long-standing partner in automation, robomotion has developed a fully automated process for our baked snacks that seamlessly integrates every step. With high-speed robots and innovative gripper technologies, we achieve the highest quality, efficiency, and precision in processing and packaging our BiFi baked snacks, all while adhering to the required hygiene standards.

N.N., LSI – Germany GmbH

The challenge

Jack Link’s BiFi products, especially the popular BiFi Rolls wrapped in dough, enjoy widespread popularity worldwide. After successfully implementing a fully automated packaging line for mini salamis in 2006, the next milestone was automating the baked goods production.

The automation of baked goods production presented numerous challenges. One of the key requirements was adhering to the strict hygiene standards essential in food production. At the same time, efficient primary and secondary packaging needed to be ensured. Another important aspect was comprehensive quality control.

The fully automated dough wrapping process for BiFi Rolls was particularly complex. It was essential to place the sausages precisely onto the dough. The integration of automated handling for both empty and filled baking trays was crucial to streamline the entire production process and maximize production efficiency.

The solution

To meet the requirements of the production process, robomotion developed a comprehensive automation solution comprising several key steps:

Step 1: Placing the sausages on the dough sheet

robomotion uses high-speed ABB Delta Robots designed specifically for high-speed pick-and-place tasks to efficiently process the BiFi sausages. These robots can separate, pick, and precisely place up to 370 sausages per minute from bulk onto the dough sheet. Utilizing the PickMaster software along with our innovative roboVision image processing system, we were able to reliably achieve the required performance and maintain high-quality standards.

Step 2: Handling the dough pieces and baking trays

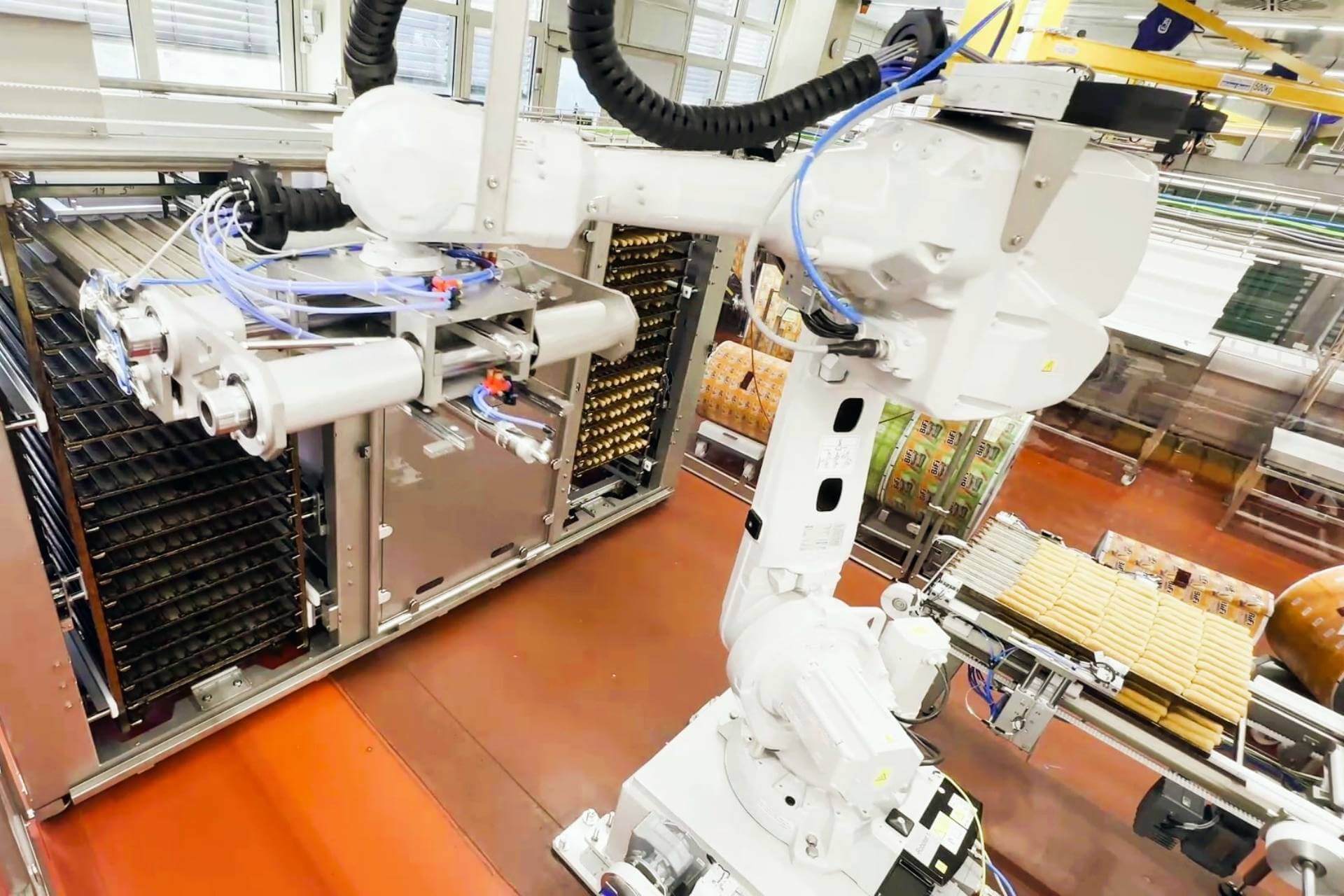

After placing the sausages, the dough pieces are placed onto baking trays and transported into ovens using rack trolleys. This step employs a 6-axis robot with a sophisticated gripper system capable of handling two empty or fully loaded trays simultaneously. This allows for the seamless movement of up to 10 trays per minute in and out of the rack trolleys, significantly speeding up the production process.

Step 3: Automated packaging

After baking, the products are placed in the packaging machine fully automatically. The previously used tray handling system is used again, but in reverse order. This time, the task is to remove the baked products from the tray, adjust their position and spacing to the packaging format and insert them precisely into the cavities of the thermoformed film.