Bild ist im Hintergrund eingefügt – mit einer Höhe von 50vh – Dieser Text ist Transparent

Ankerkraut GmbH

Automation in the World of Flavour

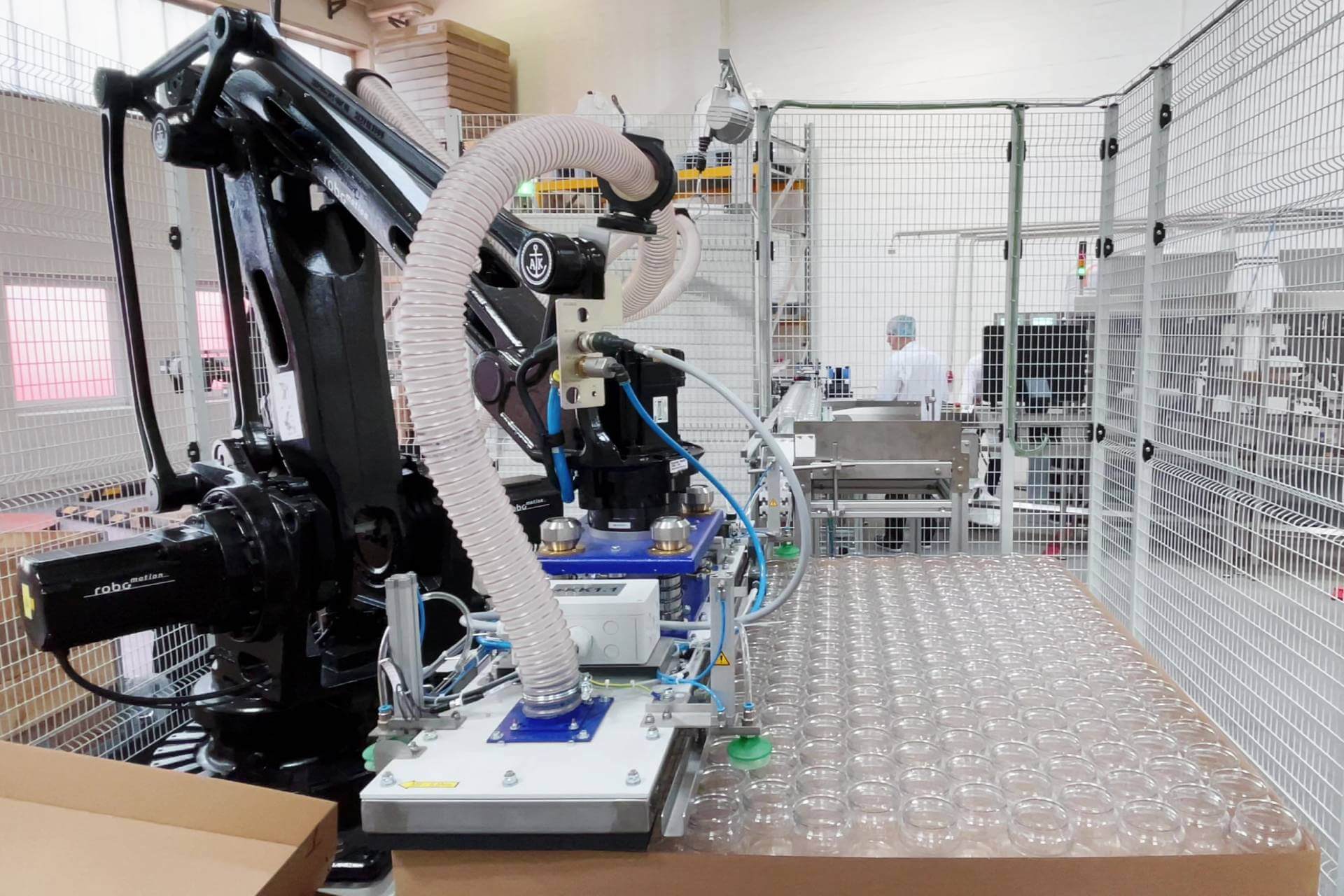

Automated depalletizing and end-of-line packaging of spice jars at Ankerkraut GmbH

The Hamburg-based spice company Ankerkraut was founded in 2013. The family business offers flavourful enjoyment without artificial flavour enhancers and is known for its high quality in the spice market. Today, Ankerkraut products are available in over 5,500 stores across Europe. In 2022, Nestlé acquired a majority stake in the spice start-up.

Food / Food Packaging

Ankerkraut GmbH

The Challenge

Automating Ankerkraut’s production processes came with specific requirements for precision and adaptability.

Until now, depalletizing and packaging the spice jars and shakers had been done manually – a time-consuming process that limited both efficiency and scalability. The challenge was to develop an automated solution that could be integrated into the existing system in a very confined space – and withstand the unique production conditions, particularly the high levels of spice dust in the air. On top of that, the system needed to safely and quickly handle various packaging types and product heights.

The Solution

An automation solution built for tight spaces and high dust exposure: robomotion implemented a compact and efficient depalletizing and packaging setup for Ankerkraut.

A 4-axis palletizing robot handles the depalletizing of spice jars and shakers. Before each layer is removed, the pallet is measured and checked for tilt, and the layer height is also recorded. A custom sponge gripper ensures that products of varying heights are safely picked from the pallet and transferred onto the conveyors using a servo pusher – all at speeds of up to 120 units per minute. After each layer is emptied, the intermediate layer is removed using a dedicated gripper function, preparing the pallet for the next cycle.

Secondary packaging is handled by a 6-axis robot, which simultaneously erects two cartons and automatically fills them with six jars each. The cartons are then folded via rails, sealed with hot glue, and precisely closed with a stamp. Finally, the finished boxes are placed onto a pallet in a predefined pattern – all within a compact footprint and despite the challenges of spice dust in the air.