Image is inserted in the background – with a height of 50vh – This text is transparent

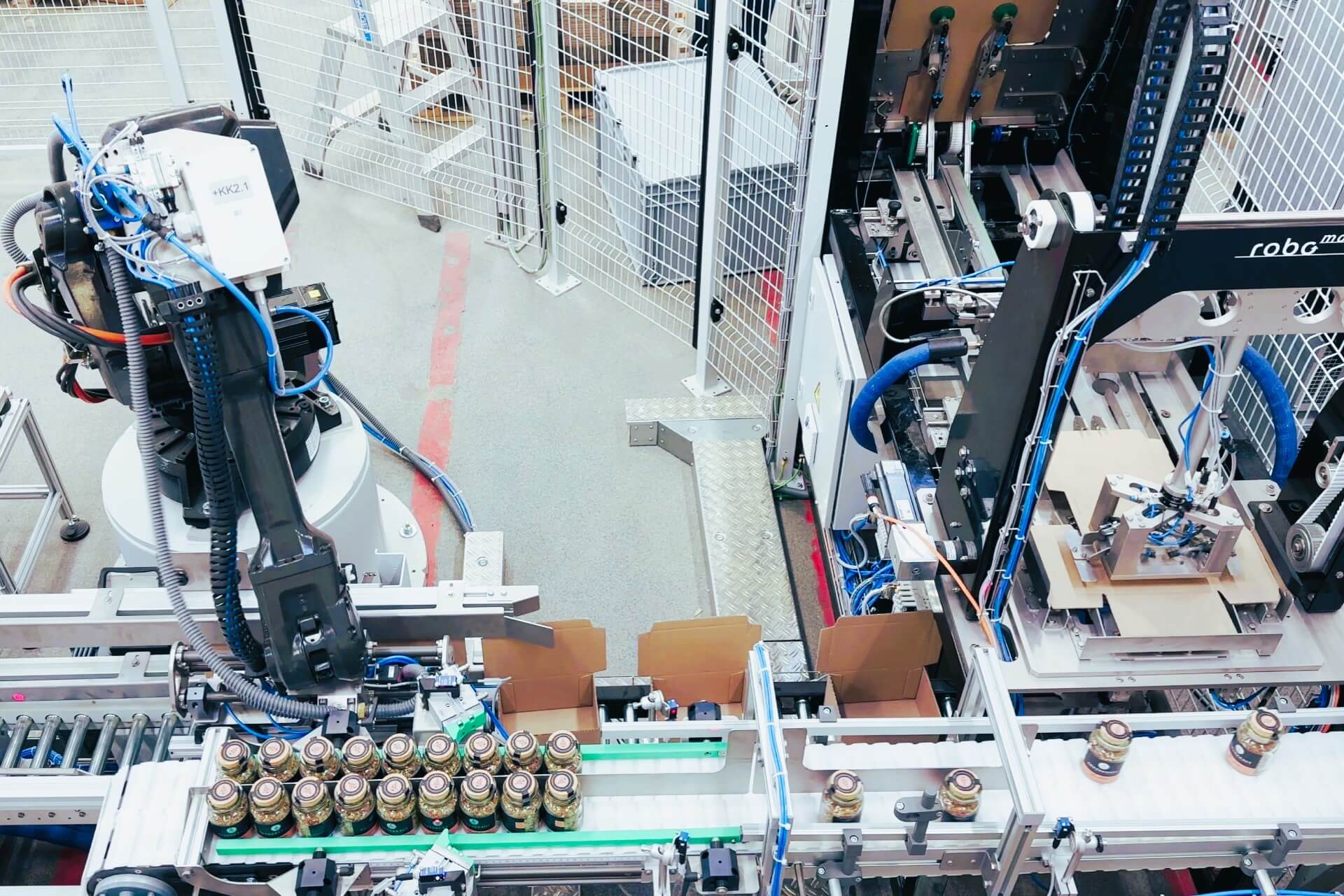

Packing

Packaging is an important process in every industry to ensure that products reach their destination safely. In addition to the protective function, sustainability and product marketing play a major role. This entails constant changes – different materials, a different product design. In other words, there are many requirements that need to be reconciled.

With our automation solutions, you are well equipped. At robomotion, we ensure that your products are safely and reliably inserted into the packaging. After the packaging process, we develop space-saving solutions that pack tested, OK goods into cartons and, if required, accompany the entire process through to palletizing and leaving the production line.

From primary to secondary to tertiary packaging, we cover all packaging stages and understand the specific requirements of your industry. We ensure that only flawless goods reach your customers.

Do you want to: